Vestrex

Maptek Data System

Maptek Compute Framework

Maptek Orchestration Environment

Join our early access program to unlock value for your organisation.

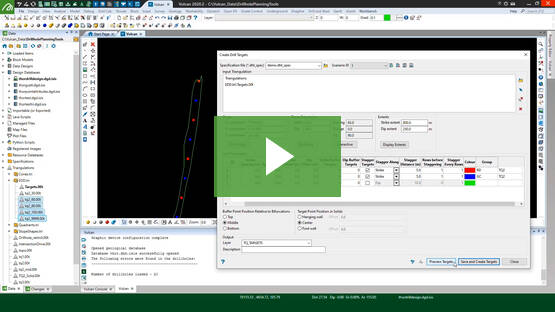

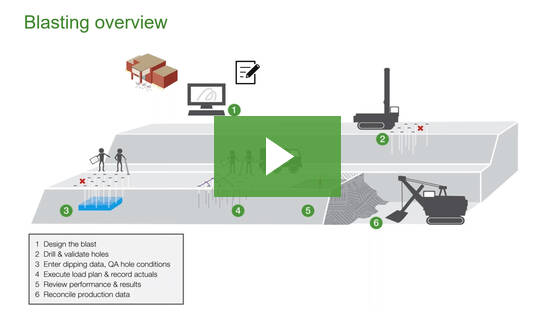

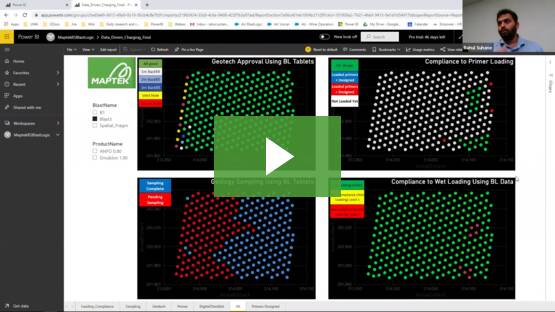

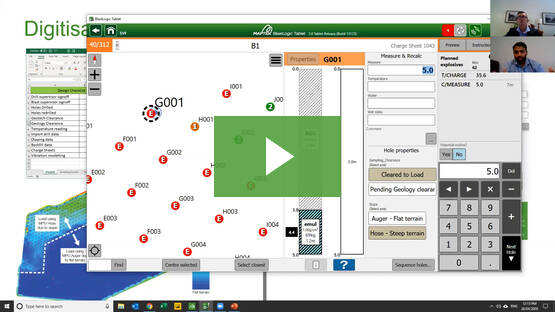

BlastLogic

Drill & blast management

Evolution

Interconnected mine scheduling

VisionV2X

Reliable proximity awareness underground

GeoSpatial Manager

Dynamic survey surface updates

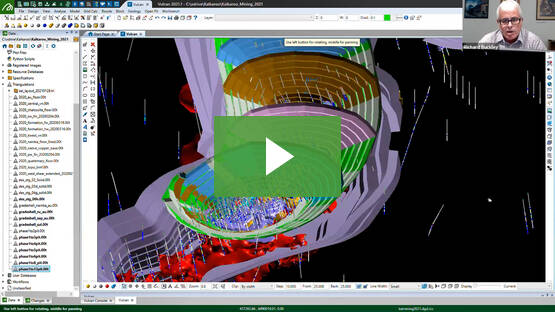

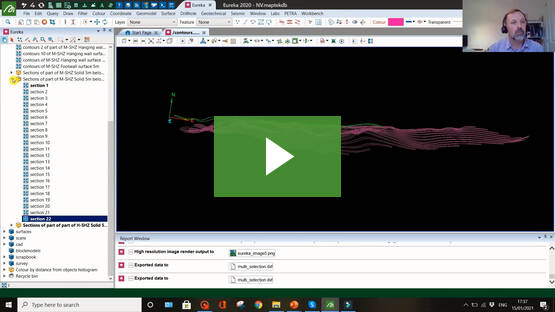

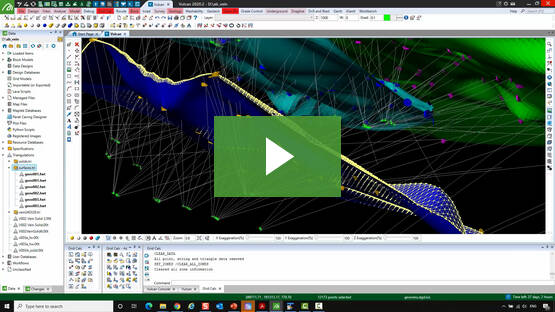

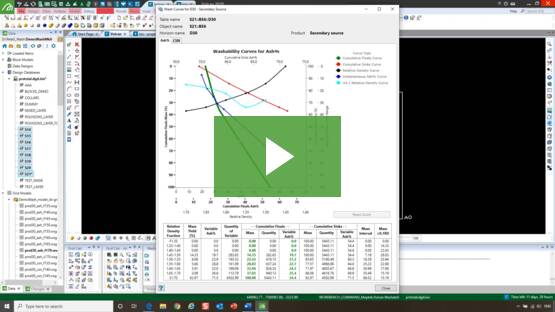

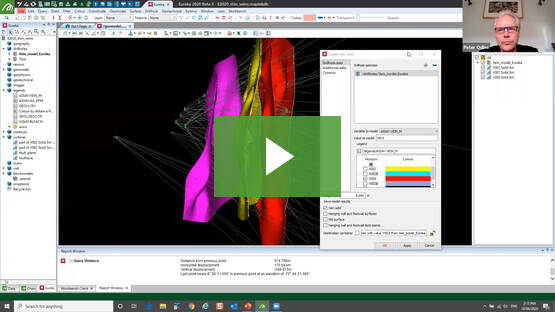

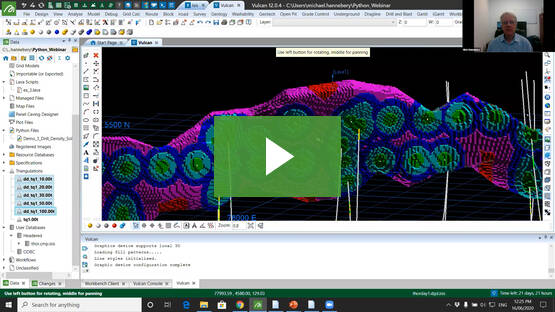

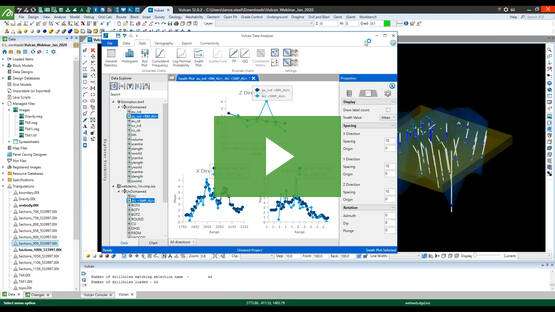

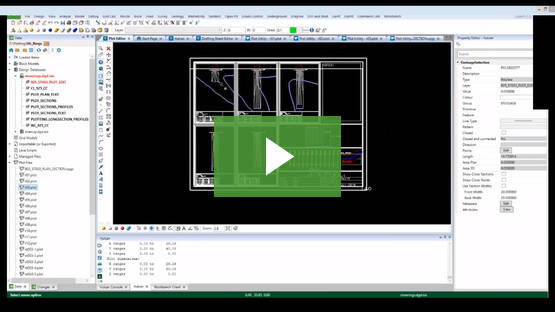

Vulcan

3D mine planning & geological modelling

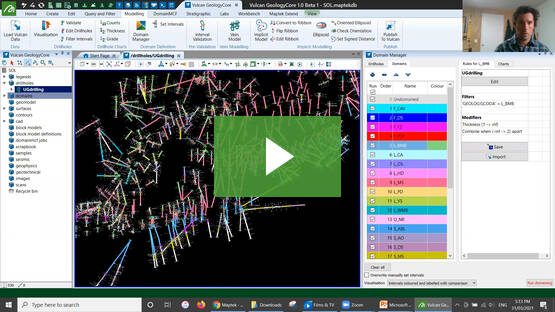

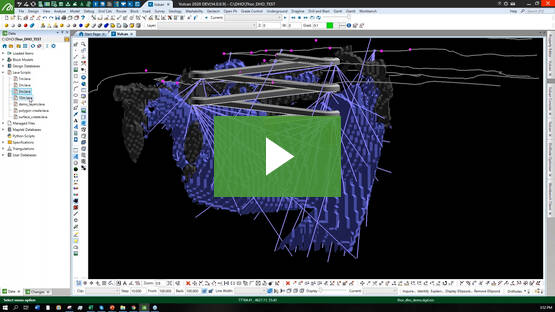

GeologyCore

Streamlined geological modelling workflow

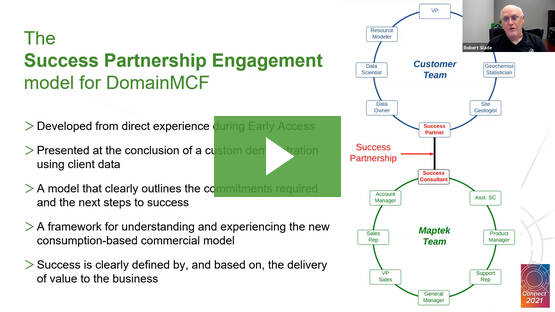

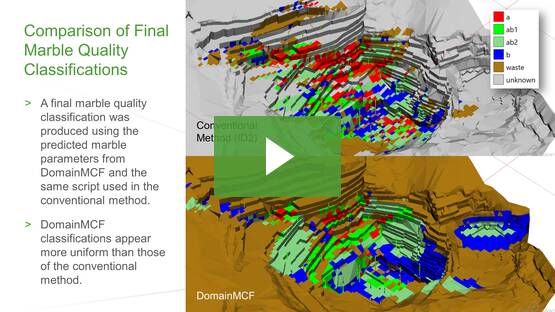

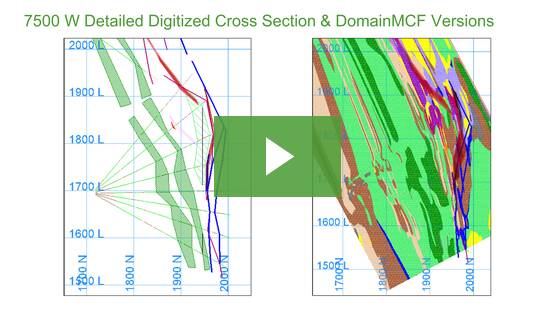

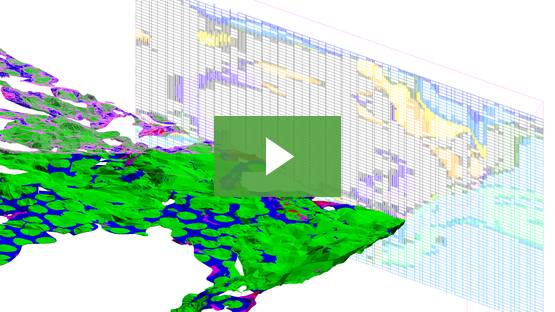

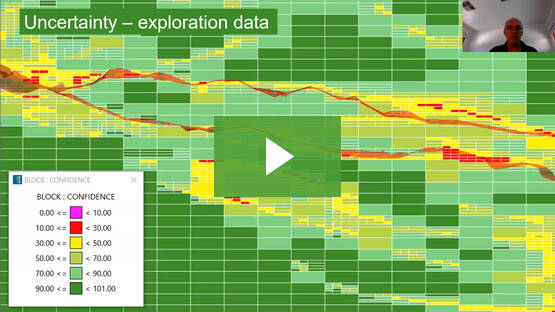

DomainMCF

Machine learning assisted domain modelling

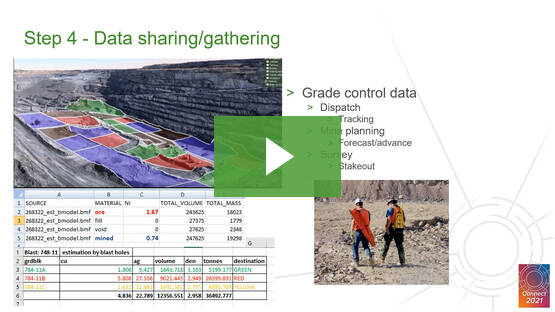

Maptek Resource Tracking

Material tracking & reconciliation systems

Laser Scanners

3D laser scanning & imaging

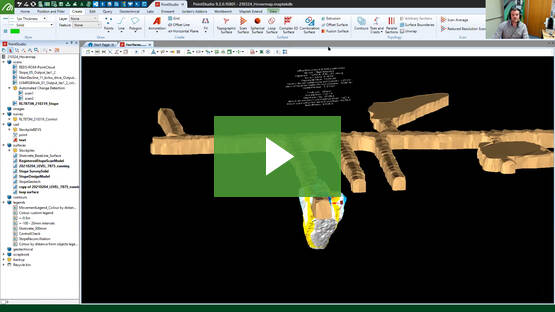

PointStudio

Point cloud processing & analysis

Sentry

LiDAR-based stability & convergence monitoring

PointModeller

Derive value from airborne or mobile sensor data