Geological modelling - a journey to the future

Maptek was founded on developing smart tools to help geologists. Forty years on a new, single interface to geological modelling allows us to consider geology and mining workflows as one continuous ecosystem. The new approach melds technologies and compute frameworks to deliver benefits for geologists and engineers alike.

Producing complex financial models for an open cut multi-element operation

Explore a mine planning workflow that starts with pit optimisation and automated pit design in Vulcan that flows into pit staging and scheduling with haulage in Evolution. Learn how Havilah Resources applies Maptek software technology to produce complex financial models for their open cut copper-gold operation.

An award-winning approach to going digital in underground mining

The introduction of electronic devices underground has changed the way we work. At Anglo American, this means a wide range of production, safety and environmental data is now available at operators’ fingertips. Learn how this improved communications and removed paper forms, assisting Anglo American’s transformation roadmap.

Good technology speaks for itself

Accurate site survey drives safe, productive operations and guides adherence to plan, minimising unforeseen costs. Efficient collection and reporting of data must consider the contextual needs of the teams who use it. Hear from our panel about how the ideal technology partnership arms survey professionals to exceed their goals.

Extending the orbit for on-earth extreme environment mineral explorers

Watch this webinar to hear about Fleet Space Technologies role in the Seven Sisters mission, and how challenges in space are already being applied to on-Earth exploration via passive seismic tomography sensing techniques. Discover the exciting results arising from how mining companies use the new 'cereal box-sized' nanosatellites to identify vast, remote areas for exploration.

How MAXTA digital mine-to-mill and pit-to-port software sustains mine value chain optimisation

Watch this webinar to learn how digital twin technology enables machine learning to feed back actual mine and plant performance in operational decision making. PETRA's MAXTA software portal allows access to a suite of applications along the entire value chain for improving geometallurgical prediction, simulating drill and blast performance and optimising plant set points to maximise ore recovery.

The 5 Ws of optimisation - Who, What, When, Where, Why (and How)

Artificial intelligence and optimisation methods are the new paradigm for handling complex optimisation problems. Find out why these techniques are the best fit for integrated planning and decision-support systems such as drill & blast, scheduling and beyond, where multiple constraints are being imposed on a mining problem.

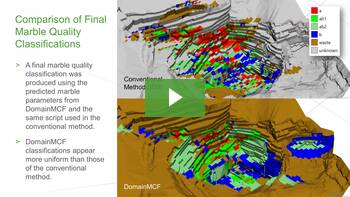

Machine learning and cloud computing frameworks in engineering

DomainMCF applies machine learning to revolutionise modelling of domain boundaries. Parallel Maptek machine learning and cloud compute framework projects in the engineering space are also delivering outstanding results for underground stope orientation, blast design optimisation and resource levelling allocation.

Conformance to plan in the underground environment

Collecting contextually correct and accurate data, and reporting it in near real time presents logistical and practical challenges in a 'dark' mine. Learn how the latest technology identifies and eliminates process bottlenecks, and how true connection between orebody knowledge, production and safety enables conformance to plan.

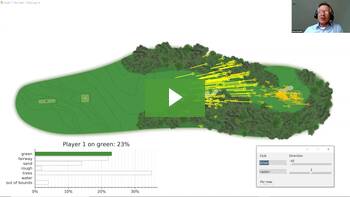

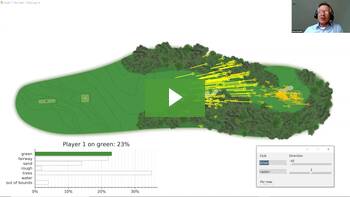

What can improving your golf game teach us about mine optimisation?

Optimisation is often referenced in mining solutions. But what does optimisation really mean, and how can it be applied to everyday problems? We unpack the mechanics of the average golf game and show how we apply optimisation techniques to improve results, before applying our learnings in the dynamic mining environment.

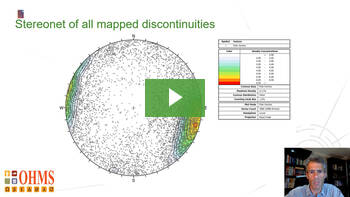

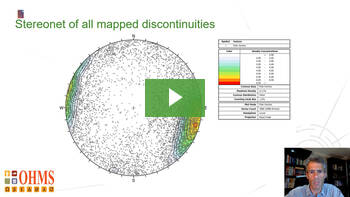

How OHMS uses remote laser scanned discontinuity data for key block analysis

Laser scanning on rock slopes at the Pilanesberg Platinum mine revealed that the orientation of the wall relative to discontinuity sets yielded incomplete structural data, leading to potentially biased discontinuity mapping. This presentation shows how the orientation bias was identified and resolved, to ensure that the structural database was complete and effective in identifying and quantifying the slope stability hazard.

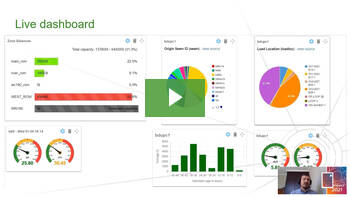

Accurate, real-time production performance tracking and visualisation

A holistic approach to tracking and modelling production performance with Maptek material tracking closes the loop through effective, real time reconciliation of inventory and qualities through mining, blending and processing stages. Learn the insights you can gain from a graphical view of the status of the mine, alongside performance metrics against plans and goals.

“Bigger isn’t always better”- Alternative mining approaches for narrow vein orebodies

Selection of development fleet and excavation dimensions can have a significant effect on project capital and operating costs for narrower orebodies. Hear how smaller, narrow vein specific equipment and methods allow mechanised mining to be selective and cost-effective, with case studies showing how a low volume approach has provided the opportunity to significantly change project metrics and viability.

The minerals business of the Bronze Age: Origins of geopolitical and economic power struggles

The Bronze Era was characterised by an expanding cultural universe of opulence, differentiation between rich and poor, contacts amongst nations and sagas of violence and drama. Access to tin, a relatively scarce metal used in the production of bronze, was a trading priority during that period. Hear how the close of the Bronze age led to voyages of discovery across the world, opening up new long-distance commercial contacts between traders.

Hutton's Unconformity: The father of geology (now in 3D)

James Hutton devoted his scientific knowledge, powers of observation and philosophical mind to the new subject of 'geology'. Where past theologians had estimated the earth to be thousands of years old, Hutton was first to determine that the Earth was millions of years old and continually being formed. Learn about the history of geological thinking and the tremendous developments made by Hutton in the development of modern geology.

British mining renaissance and the future of battery minerals

Mineral extraction will play a crucial role in the coming energy transition with demand for lithium projected to rise nearly 1000% by 2050. It is vital that these minerals are extracted in a responsible manner. Hear how Cornish Lithium is exploring for lithium in the south west of England, aiming to extract mineral resources using new technologies in the most environmentally responsible way possible.

Best practices in grade control and reconciliation

Understanding grade distribution, optimising mining selectivity and controlling mining dilution and losses through good grade control routines are essential for achieving the mine plan. Hear from industry experts from SRK and Maptek who discuss best practices in grade control and reconciliation, and how effective reporting mechanisms can help improve business performance.

Application of DomainMCF to marble quality classification

This presentation applies DomainMCF to model the spatial distribution of marble quality parameters from an operational marble quarry in northeastern Greece. Learn how machine learning systems take advantage of the computing power of personal, embedded and cloud systems to rapidly build models of real processes, and how the results compare to those produced by a conventional estimation method.

Using drill & blast data to drive intelligent decisions

Hear from Sawyer Schrader, Mining Engineer at Maptek, as he demonstrates how to drive intelligent decision making at mine sites by utilising results from a drill and blast management solution like Maptek BlastLogic. See how these results can drive proactive decisions, improve efficiency, and save your company money with minimal disruption to your site and blasting workflows.

An exploration of grade control

Hear from Cesar Carrasco, Customer Success Manager at Maptek, as he explores his favourite grade control tools to help maximise the value of your deposit.

Past, present, and future of data interoperability

As demand for mineral resources continues to grow, so does the importance of data interoperability at mine sites. Watch this webinar to hear Nick Venter, US Director of Sales at Maptek, and Jesse Oldham, Global Product Strategy Manager at Maptek, discuss the interoperability of Maptek products.

How to successfully establish business value with DomainMCF for geological modelling

Take a journey through DomainMCF, Maptek’s new machine learning application for domain modelling, and experience a proven customer success model for evaluating this exciting new technology with Early Access industry partners. See how you can benefit from the latest Maptek solution and whether your challenging geological data might be a good fit.

The journey from paper to digital mapping

Hear from our panel of diverse industry professionals as they discuss their journey from paper to digital mapping, covering mapping practices and their views on digital mapping in the field. Maptek Geologist Maureen Moore hosts Terry Pavlis from the University of Texas, Ryan Pinguely from OceanaGold, and Nick Vetz and Mackenzie Sorensen from Rio Tinto Kennecott.

Maptek scanners through the years: A transformation

Maptek laser scanners and PointStudio software have helped mining professionals visualise their point-cloud data for over 20 years! For our 40th anniversary, we honour that history with a laser scan of downtown Vancouver at sunset. Experience a breathtaking Vancouver visual brought to life by some of our latest imaging and scanning technologies.